Advantageous features and introduction of ultrasonic acoustic chemical emulsification

Ultrasonic acoustic chemical emulsification is a technology that uses ultrasonic waves to realize liquid emulsification, which is widely used in food, medicine, cosmetics and other fields. Its core principle lies in dispersing immiscible liquids into tiny droplets to form stable emulsions through the cavitation effect of ultrasound.

Advantages and characteristics of ultrasound

1. Certain high efficiency

The use of ultrasonic waves can achieve rapid emulsification: ultrasonic waves can disperse the liquid into tiny droplets in a very short time, significantly improving the efficiency of emulsification. Uniform dispersion: the cavitation effect of ultrasound makes the dispersed droplets more uniformly distributed, the emulsion stability is higher, more effective.

2. Certain energy saving and environmental protection effect

Low energy consumption and no pollution can be realized: compared with traditional emulsification methods, ultrasonic emulsification has lower energy consumption, which meets the requirements of green production. There is no need to add chemical emulsifiers in the process, reducing environmental pollution.

3. Easy to operate

Our equipment is easy to operate: ultrasonic acoustic chemical equipment is easy to install and work stably. It can realize automatic operation, reduce manual intervention and improve production efficiency. Contact ultrasound can spread the energy into the liquid better.

4. Application industries

Applicable to cosmetics and other fields to meet different emulsification needs. It can produce nano emulsion, micro emulsion and many other types.

5. Wide range of products with guaranteed quality

Our products can meet various production needs from laboratory to production line. The ultrasonic energy can be controlled with different amplitudes.

Principle and advantageous features of ultrasonic extraction

Ultrasonic extraction is a technology that uses the high-frequency vibration and cavitation effects of ultrasound to efficiently extract target components from solid or liquid samples. This technology is widely used in the fields of natural product extraction, pharmaceutical ingredient separation, food processing and environmental analysis. By immersing the ultrasonic probe directly into the sample, the contact ultrasonic equipment is able to efficiently transfer ultrasonic energy and significantly improve the extraction efficiency.

Features of ultrasonic extraction

1. Contact processing

Contact ultrasonic equipment through the probe directly immersed in the sample, can efficiently transfer ultrasonic energy, to ensure that the energy is focused on the sample, to improve the extraction efficiency.

2. Strong local effect

The effect of ultrasound is mainly concentrated in the area near the probe, which can realise the local treatment of the sample and reduce the impact on the surrounding environment.

3. Suitable for small samples

Contact ultrasonic equipment is particularly suitable for small volume sample extraction, can be in the micro-conditions of efficient extraction of the target components.

4. Can be combined with other technologies

Ultrasonic extraction can be combined with other extraction techniques (such as solvent extraction, supercritical fluid extraction, etc.) to further improve the extraction efficiency and quality.

5. Fast and efficient

Ultrasonic extraction can be completed within a few minutes of the traditional method requires hours or even days of extraction process, significantly improve the efficiency of the experiment.

6. Flexible equipment

Contact ultrasonic equipment is usually compact, easy to use in the laboratory or industrial production, while supporting a variety of sample containers and processing scale.

Summary

Ultrasonic extraction technology can efficiently and rapidly extract target components from a wide range of samples through cavitation and mechanical effects. With its high efficiency, ease of operation and environmental safety, contact ultrasonic equipment shows a wide range of application prospects in the fields of natural product extraction, pharmaceutical ingredient separation, food processing and environmental analysis. With the continuous development and optimisation of ultrasonic technology, ultrasonic extraction will play an important role in more fields, providing strong technical support for scientific research and industrial production.

Ultrasonic dispersion

Ultrasonic dispersion technology is a physical method that uses the high-frequency vibration of ultrasound to achieve material dispersion, fragmentation or homogeneous mixing. Due to its high efficiency, uniformity and non-thermal effect, this technology has been widely used in chemical industry, material science, biomedicine and other fields.

The core mechanism of ultrasonic dispersion is the cavitation effect of ultrasound. When ultrasonic waves act on a liquid, they produce high-frequency vibrations and form tiny bubbles. These bubbles expand and contract rapidly under the action of sound waves, and eventually rupture, producing strong shock waves and micro-jets. This cavitation effect effectively breaks up particles, disperses agglomerates, and promotes homogeneous mixing of substances.

The main applications of ultrasonic dispersion are in the dispersion of nanomaterials, emulsion preparation, cell crushing, and chemical reaction promotion.

The advantage of ultrasonic dispersion is that it can achieve the uniform dispersion of substances in a short time and significantly improve the working efficiency. The dispersion effect is uniform and the particle size distribution is narrow. It is suitable for fields with high requirements for dispersion.

Dispersion is mainly achieved through mechanical action, and is suitable for heat-sensitive substances. Can be used in a wide range of systems such as liquids, suspensions and emulsions.

Ultrasonic dispersion technology has become an indispensable tool in modern industry and scientific research due to its high efficiency, homogeneity and non-thermal effect. By reasonably controlling the operating parameters, ultrasonic dispersion can achieve ideal dispersion effect and provide strong support for the development of nanomaterials, food chemicals and other fields.

Ultrasonic homogenisation

Ultrasonic homogenisation technology is a physical method that uses high frequency vibration of ultrasonic waves to achieve crushing, dispersing and homogeneous mixing of particles in liquids. Compared with the traditional mechanical homogenisation method, ultrasonic homogenisation has the advantages of high efficiency, simple operation and wide range of application, so it has been widely used in the fields of food, chemical industry, medicine and cosmetics.

The main applications of ultrasonic homogenisation are in the food industry, cosmetics and skin care products, pharmaceutical technology, biotechnology, chemical material treatment, wastewater treatment and so on.

The advantage of ultrasonic homogenisation is that ultrasonic homogenisation can achieve the refinement of particles and the uniform mixing of liquids in a short period of time, which significantly improves the production efficiency. The homogenising effect is more uniform and the particle size distribution is narrower, which makes it suitable for fields with high homogenising requirements. Suitable for heat sensitive substances. The equipment is simple to operate and easy to maintain. No need to add any chemical reagent during homogenisation, reducing environmental pollution.

Ultrasonic homogenising technology has become an indispensable tool in modern industrial production due to its high efficiency, homogeneity and non-thermal effect. Its wide application in food, pharmaceutical, cosmetic, chemical and other fields provides strong support for product quality improvement and production efficiency optimisation.

Ultrasonic welding

Ultrasonic hand welding gun plastic welding technology is an advanced method of using ultrasonic vibration energy to achieve the connection of plastic materials. Due to its high efficiency, environmental protection, easy operation and other characteristics, the technology has been widely used in automotive manufacturing, electronic appliances, medical equipment, packaging and other industries.

Ultrasonic plastic welding is through the transducer will be converted into mechanical vibration of the electrical signal, welding head will be vibration energy transfer to the plastic workpiece. Our hand welding torch is designed to be lightweight and flexible, suitable for manual operation, especially for welding small workpieces or complex shaped workpieces. We also have ultrasonic transducers, vibrators, and horns specifically designed for rack welding, and can provide products and services adapted to rack welding.

Ultrasonic plastic welding can be used in

1.Automotive manufacturing: in automotive manufacturing, ultrasonic welding can be used to weld plastic parts such as dashboards, bumpers, door interiors and so on. Its high efficiency and reliable performance can fully meet the automotive industry on the welding quality of ultra-high requirements.

2. Electronic and electrical appliances: ultrasonic hand welding gun is widely used in electronic and electrical appliances industry, such as welding switches, sockets, battery cases, and other plastic parts. The non-thermal effect is particularly suitable for welding heat-sensitive electronic components.

3. Medical equipment: in the manufacture of medical equipment, ultrasonic welding is usually applied to welding infusion tubes, filters, syringes and other plastic products. The welding process does not require the addition of chemical substances, in line with the health and safety requirements of medical devices.

4. Packaging industry: ultrasonic welding can be used to weld plastic packaging containers, lids, films, etc., to ensure that the packaging is sealed and beautiful.

5. Home appliance manufacturing: In home appliance manufacturing, ultrasonic welding is used to weld plastic parts of washing machines, refrigerators, air conditioners and other products to improve production efficiency and product quality.

Ultrasonic welding process usually takes only a few seconds to complete, significantly improving production efficiency and more environmentally friendly, welding without the use of adhesives or solvents, reducing pollution. The welded joints are strong, airtight and aesthetically pleasing. Suitable for a variety of thermoplastics, such as ABS, PC, PP, PE, etc..

Ultrasonic welding technology has become an indispensable tool in modern manufacturing industry due to its high efficiency, environmental protection and easy operation. Its wide application in automotive, electronics, medical, packaging and other fields provides strong support for product quality improvement and production efficiency optimisation.

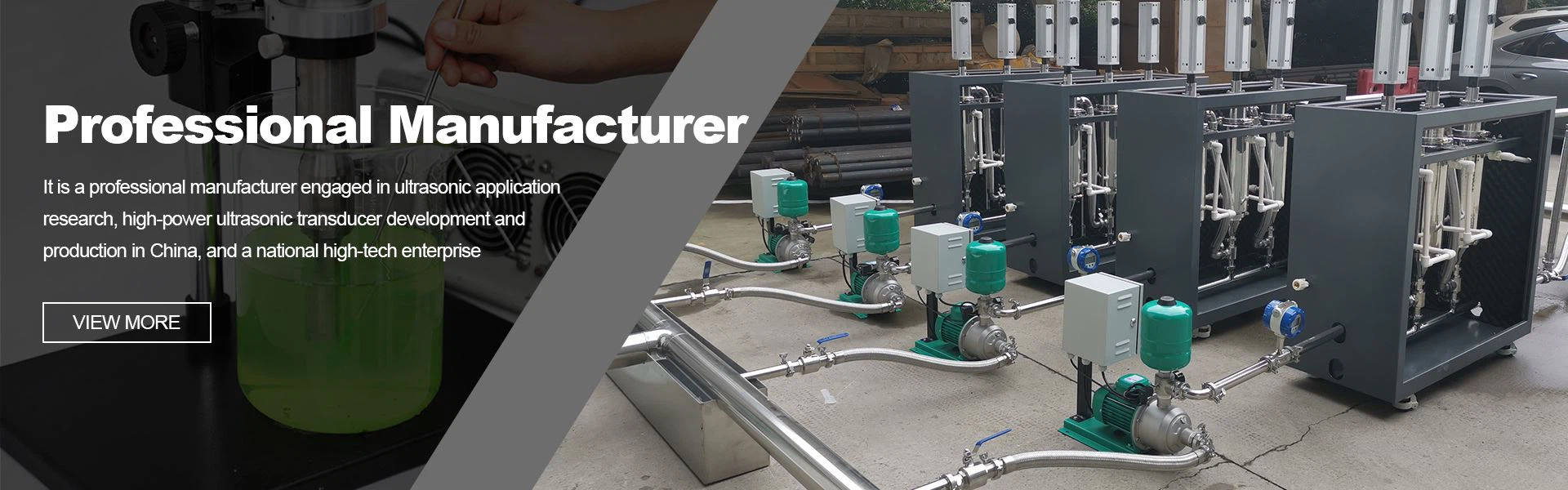

Hangzhou Success Ultrasonic Equipment Co., Ltd. focuses on research and development of high-power ultrasonic equipment, and can provide one-stop product services from experiment to production line.

Ultrasonic Defoaming System

Ultrasonic defoaming technology is an advanced method of eliminating air bubbles in liquids by utilising the high-frequency vibration energy of ultrasound. The technology destabilises the bubbles through the mechanical action of ultrasonic waves, causing them to break up or merge rapidly, thus reducing or eliminating foam. Ultrasonic defoaming technology is widely used in the chemical, food, pharmaceutical and coating industries, providing an efficient solution for foam control in the production process.

Ultrasonic defoaming is mainly used in

1. Chemical industry: In chemical production, ultrasonic defoaming is used to eliminate foam in reaction kettles, stirred tanks and other equipment to improve production efficiency and product quality.

2. Food and beverage industry: ultrasonic defoaming technology can be used to eliminate foam in food processing, such as juice, beer, dairy products, etc., to ensure product taste and appearance.

3. Pharmaceutical and biotechnology: In pharmaceutical production, ultrasonic defoaming is used to eliminate air bubbles in medicinal liquids, culture media and other liquids, to ensure the purity of drugs and the accuracy of biological experiments.

4. Coating and printing ink industry: ultrasonic defoaming technology can be used to eliminate air bubbles in coatings and printing ink to improve the uniformity and surface quality of the coating.

5. Wastewater treatment: In wastewater treatment, ultrasonic defoaming is used to eliminate bubbles in aeration tanks and improve treatment efficiency.

6. Laboratory research: ultrasonic defoaming technology is used in the laboratory to eliminate air bubbles in experimental liquids to ensure the accuracy of experimental results.

The advantage of ultrasonic defoaming is that ultrasonic waves can eliminate air bubbles in the liquid in a short period of time, significantly improving production efficiency. And there is no need to add chemical defoamer, reducing environmental pollution. Ultrasonic waves are mainly realised by mechanical action and are suitable for heat sensitive liquids. The ultrasonic energy is evenly distributed to ensure that each area receiving the energy has the same defoaming effect. At the same time, it is suitable for water-based, oil-based, high viscosity and other liquids.

Ultrasonic defoaming technology with its high efficiency, environmental protection, non-thermal effect, has become an indispensable tool in modern industrial production. It is widely used in chemical, food, pharmaceutical, coating and other fields, for product quality improvement and production efficiency optimisation provides strong support.

Ultrasonic Atomisation

Ultrasonic atomisation technology is an advanced method of converting liquids into tiny droplets by using the high frequency vibration energy of ultrasonic waves. The technology produces capillary waves on the surface of the liquid through the mechanical action of ultrasonic waves, thus breaking the liquid into micron or even nano-sized droplets. Ultrasonic atomisation technology is widely used in medical, humidification, air purification, cosmetics and other fields, providing efficient solutions for liquid dispersion and aerosol preparation.

Ultrasonic atomisation is mainly used in

1. Humidification and air purification: ultrasonic atomisation technology is widely used in household and industrial humidifiers to improve air humidity by converting water into tiny droplets. In special working conditions these droplets will adsorption of dust in the air to bring down.

2. Cosmetics and skin care products: in the cosmetics industry, ultrasonic atomisation is used to prepare spray-type skin care products, such as moisturizing spray, sunscreen spray. The atomised droplets are easier to be absorbed by the skin and improve the effect of the product.

3. Agriculture and horticulture: ultrasonic atomisation technology can be used for humidification and pesticide spraying in agricultural greenhouses to improve pesticide utilisation and crop growth efficiency.

4. Industrial spraying: In the industrial field, ultrasonic atomisation is used for spraying paints, inks and other liquids to achieve a uniform coating effect.

5. Laboratory research: Ultrasonic atomisation technology is used in the laboratory to prepare aerosols or nanoparticles to support materials science and chemistry research.

With its high efficiency, uniformity and controllability, ultrasonic atomisation technology has become an indispensable tool in modern industry and life. Its wide application in medical, humidification, cosmetic and agricultural fields provides strong support for product quality improvement and productivity optimisation.