3 in 1 Ultrasonic Recirculation Setup With Flow Cell System

Description

Technical Parameters

Product introduction

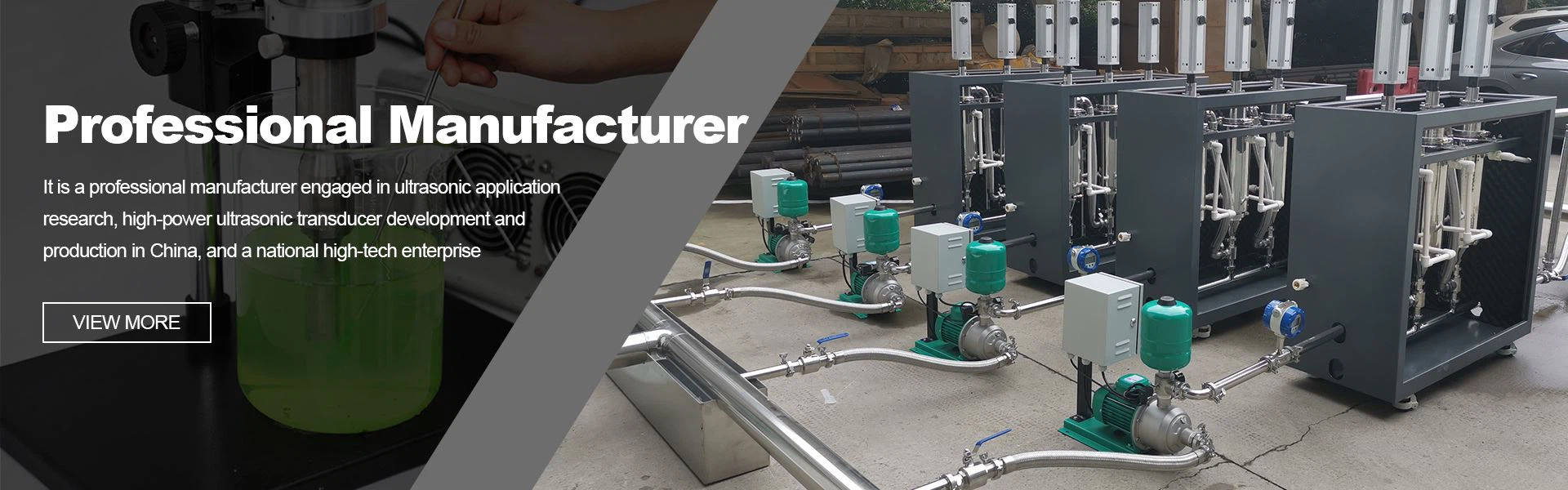

The YPS61B-MB is a robust and reliable system for all kind of ultrasonic liquid processes. Important applications for the ultrasonic processor YPS61B-MB are the breakage (particle size reduction), deagglomeration & dispersion of nano materials, the functionalization of nano particles, emulsification, the production of biofuels (e.g. biodiesel, bioethanol), the formulation of paint & coatings, and various sono-chemical applications (e.g. sono-catalysis, phase transfer catalysis, precipitation, sol-gel routes). With 2000W ultrasonic power, YPS61B-MB handles easily applications in pilot and large scale. Corresponding ultrasonic processor provide the required intensity of ultrasonic treatment of the liquid. Corresponding flow cells are offered for continuous operation. Sound protection casings complete the ultrasonic system based on YPS61B-MB. The picture above, shows a disintegration system of 3x Ultrasonic Processor . The combined power of 9kW is used for the processing of approx. 1-3m³/hr.

There are three processors in one processing cabinet. They are used in three reactors with a capacity of 3.5L (the three reactors are interconnected). The reactor has an cooling water jacket. The processor, reactor and liquid pipe are all connected with gaskets and quick clamp.

We installed Pressure sensor, Flow sensor and Temperature sensor in the pipeline, which could transfer the data to PLC and use HMI to setting alarm value to achieve best performance.

Our equipment has a certain noise reduction function, which can reduce the noise during operation to less than 85 decibels. And our devices reserve interfaces for devices such as pumps, filters, heat exchangers and product collection/storage units for easy connection.

Technical specifications

| Model | YPM11-M020 |

| Max Output Power | 9000W |

| Protect Level | IP20 |

| Amplitude Range | 20-100% |

| Input voltage | 380V/50HZ-60HZ |

| Construction | Ultrasonic processor + Ultrasonic generator + HMI + PLC + Sound Protect + Enclosure |

| Items | Pressure sensor + Flow sensor + Temperature sensor + Storage Tank + Blender + Pump |

| size | 805*700*1750(mm) |

Hot Tags: 3 in 1 ultrasonic recirculation setup with flow cell system, China, suppliers, manufacturers, factory

Send Inquiry

You Might Also Like