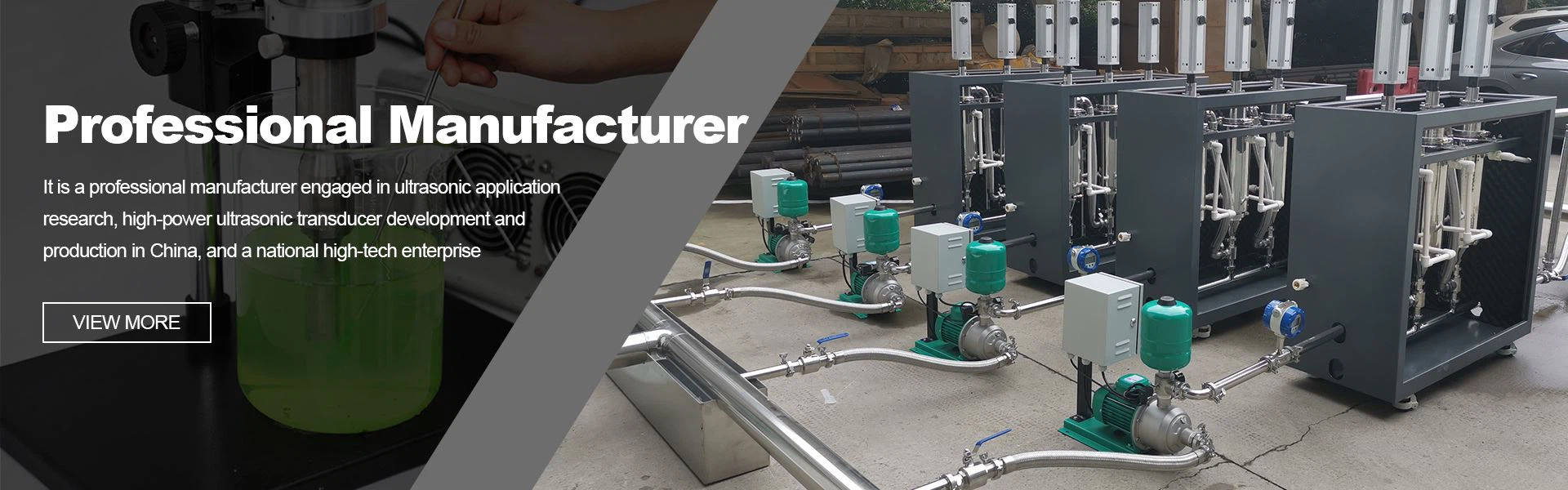

Ultrasonic Pilot Circulating System

Description

Technical Parameters

Introduction to Ultrasonic Sonochemistry

Ultrasonic sonochemistry is a field that utilizes high-frequency vibrations and cavitation effects generated by ultrasound propagating through liquids to induce chemical reactions or physical changes. The frequency of ultrasound is typically above 20 kHz. When it propagates through a liquid, it creates periodic compression and expansion, leading to the formation of tiny bubbles in the liquid. These bubbles rapidly expand and violently collapse under the action of ultrasound, generating localized high temperatures, high pressures, and intense s hear forces. This phenomenon is known as the "cavitation effect." The cavitation effect can accelerate chemical reactions, promote material mixing, disperse particles, break up agglomerates, and even initiate reactions that are difficult to achieve under conventional conditions.

hear forces. This phenomenon is known as the "cavitation effect." The cavitation effect can accelerate chemical reactions, promote material mixing, disperse particles, break up agglomerates, and even initiate reactions that are difficult to achieve under conventional conditions.

Ultrasonic sonochemistry is widely used in materials science, environmental remediation, biomedicine, food processing, and other fields. In materials science, it is commonly employed for the synthesis of nanomaterials, particle dispersion, surface modification, and other processes.

Application:

Homogenization, Cleaning, Dispersing & Deagglomeration (e.g. nano particles), Wet-milling & Grinding (e.g. nano materials), Emulsifying, Lysis & Cell Disintegration, Extraction, Sonochemistry.

Effectiveness:

High performance. ultrasonic device, automatic frequency tuning, amplitude adjustable from20% to 100%,All resuits achievedcan be scaled up linearly. transducerIP20 grade, titanium probe.Can be equipped with temperature control device, material circulation work.

Ultrasonic Extractors – For Small and Large Scale

Hangzhou Success Ultrasonic Equipment Co.,Ltd is your partner for high performance ultrasonic extraction equipment. Whether you want to produce small batches of high-quality plant extracts for your boutique brand, or want to scale up production on an industrial scale -Hangzhou Success Ultrasonic Equipment Co.,Ltd can provide you with the ideal ultrasonic extraction equipment!

Ultrasonic Extraction

Power ultrasound is a proven method for efficient and reliable extraction of active compounds including herbal/ medicinal compounds, oil, proteins and bioactives (e.g. flavones, polyphenolics, anthocyanin, aroma) from botanicals, herbs, flowers and seeds.

For ultrasonic extraction, powerful ultrasound waves are coupled into the plant-solvent mixture, so that acoustic cavitation occurs. Acoustic cavitation is described as the ultrasonically caused formation, growth, and implosive collapse of bubbles in liquids.

"During cavitation, the collapse of bubbles produces intense local heating and high pressures, with very short lifetimes. In clouds of cavitating bubbles, these hot-spots have equivalent temperatures of roughly 5000 K, pressures of about 1000 atmospheres, and heating and cooling rates above 1010 K/s. In single bubble cavitation, conditions may be even more extreme. Cavitation, then, can create extreme physical and chemical conditions in otherwise cold liquids. If liquids containing solids are irradiated with ultrasound, related phenomena can occur. Near an extended solid surface, cavity collapse becomes non-spherical, which drives high-speed jets of liquid into the solid surface. These jets and associated shock waves can cause substantial surface damage and expose fresh, highly heated surfaces. In addition, high velocity inter-particle collisions will occur during ultrasonic irradiation of liquid-powder suspensions through cavitation and the shockwaves it creates in such slurries. The resultant collisions are capable of inducing dramatic changes in surface morphology, composition, and reactivity."

These intense conditions of ultrasonic cavitation have several effects on plant material and their extractability:

overcome of cell membrane selectivity

increased mass transfer between cell inside and surrounding solvent

cell breakage

release of intracellular material

This makes sonication a highly effective extraction method. Due to the intense mechanical forces, often green and mild solvents such as water, ethanol etc. can be used.

Ultrasonic extraction shortens the extraction time and allows for a reduced and/ or milder solvent use. This means, ultrasonic extraction results in higher extraction rates and produces healthier extracts. This is due to the characteristics of its operation at low temperature both to reduce heat loss caused by temperature factors, but also to avoid the vaporization of substances due to low boiling point and also to maintain biological active substances.

Another advantage of ultrasonic extraction lies in it simple and safe use and its precisely controllable application. As a non-thermal extraction method, sonication can be carried out at low temperatures so that the degradation of heat sensitive, heat-labile substances is avoided.

Hot Tags: ultrasonic pilot circulating system, China, suppliers, manufacturers, factory

Send Inquiry