Ultrasonic Mineral Scrubbing Applications

Jul 08, 2025

Leave a message

Introduction to Ultrasonic Acoustic Chemistry Applications

Ultrasonic sonochemical equipment is mainly used for homogenising, cleaning, dispersing and deagglomerating, emulsifying, demulsifying, cell-breaking, microbial sterilisation, plant extraction, and sonochemistry.

Ultrasonic liquid handling

Ultrasonic liquid treatment is a technology based on ultrasonic cavitation effect, and its important function is to achieve the dispersion and depolymerisation of solid particles in liquids. The technology effectively improves the homogeneity and stability of the liquid by reducing the particle size of the tiny particles in the liquid, which makes it an efficient method for handling soft and hard particles. It is worth noting that the ultrasonic dispersion technology has good scalability, can be smoothly transitioned from laboratory scale to industrial production, and the treatment effect in industrial production is highly consistent with the laboratory data.

Quartz Sand Materials Report

Quartz sand is a kind of hard, wear-resistant, chemically stable silicate minerals, its main mineral composition is SiO2, quartz resources are widely used in various industrial fields. However, iron, aluminium, calcium and other impurities in quartz sand will adversely affect the quality of the product, which needs to be scrubbed to meet the ideal requirements for use.

Quartz sand raw materials

Course of events

Take 100ml of the sample and fill a beaker. Then add 300ml of water. The beaker and the sample were ultrasonically cleaned for 120 s. The cleaned sample was filtered. After filtration the sample is dried.

The dried samples were compared in colour and cleanliness with the uncleaned salvors.

Conclude

By comparison, the colour of the sample after ultrasonic cleaning will be whiter and the particles cleaner than the sample before cleaning.

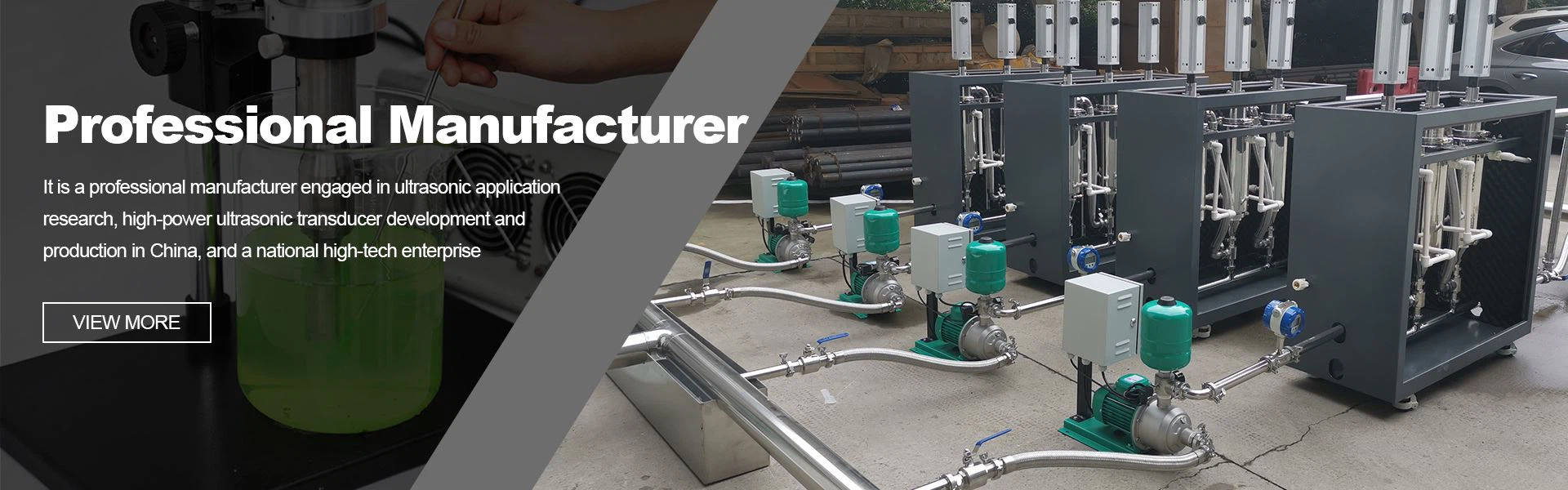

One-stop solutions from the lab to the production line

We can supply a full range of ultrasonic equipment from laboratory to production line for batch or experimental processing of any volume for dispersion and depolymerisation. Laboratory grade sonochemical equipment is available for laboratory beakers from 500 ml up to about 1 L. Industrial ultrasonic equipment is used for process development and production, and multiple sets can form a complete production line.